Our Services

Comprehensive plastic component solutions designed to meet the demanding requirements of the automotive industry.

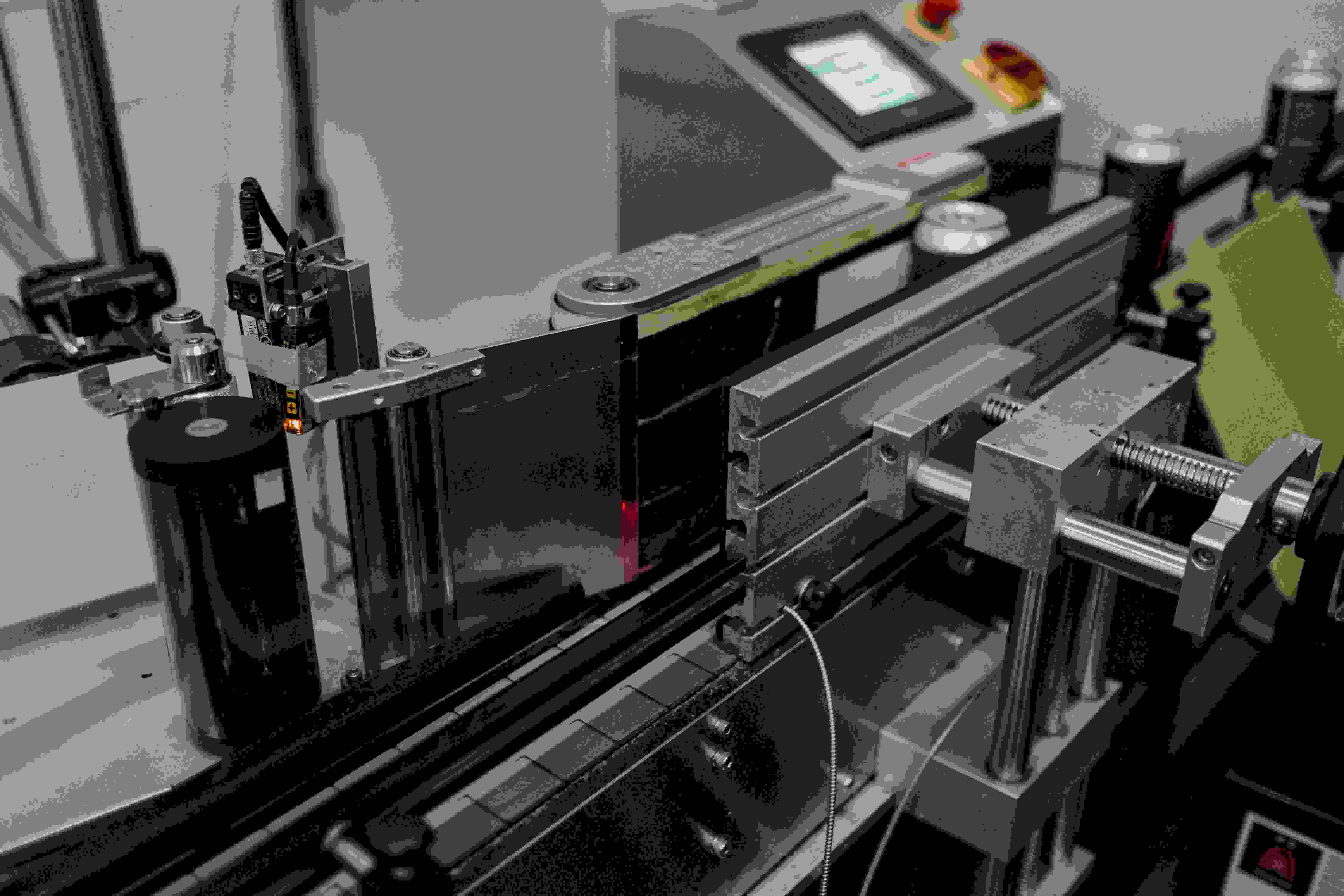

Injection Molding

High-precision injection molding services for automotive components with strict tolerance requirements and complex geometries.

Our state-of-the-art injection molding facilities are equipped with the latest technology to produce automotive components with exceptional precision and consistency. We specialize in: - Multi-cavity molds for efficient production - Complex geometries and tight tolerances - Materials selection for optimal performance - Process optimization for cost efficiency - In-mold assembly and decoration Using advanced simulation software, we optimize the molding process before production to minimize defects and ensure perfect parts every time. Our automated systems guarantee consistent quality across large production runs.

Key Features

- Precision tolerances to ±0.05mm

- Multi-cavity tooling for high volume production

- Advanced material options including reinforced polymers

- Real-time quality monitoring

- Automated parts handling and assembly

Precision Engineering

Advanced engineering solutions that optimize component design for performance, weight reduction, and cost efficiency.

Our engineering team combines decades of experience with cutting-edge CAD/CAM technologies to create optimized component designs. We employ advanced simulation tools to validate performance before manufacturing, ensuring that each component meets or exceeds requirements. Our precision engineering services include: - 3D modeling and simulation - Design for manufacturing (DFM) - Finite element analysis (FEA) - Computational fluid dynamics (CFD) - Material optimization By focusing on design optimization, we can reduce material usage, streamline production processes, and enhance component performance simultaneously.

Key Features

- Advanced 3D CAD design capabilities

- Structural and thermal simulation

- Material optimization for weight reduction

- Process optimization for cost efficiency

- Design review and validation

Custom Solutions

Tailored plastic component development to meet specific automotive applications and unique OEM requirements.

We specialize in developing custom plastic components that address specific challenges in automotive applications. Our collaborative approach involves working closely with your team to understand requirements, constraints, and opportunities for innovation. Our custom solutions process: 1. Detailed consultation to understand requirements 2. Conceptual design and prototyping 3. Material selection and testing 4. Production process development 5. Quality validation and certification We excel at creating solutions for unique applications where standard components aren't sufficient, helping automotive manufacturers differentiate their products.

Key Features

- Collaborative design process

- Rapid prototyping and iteration

- Custom material formulations

- Specialized surface finishes and textures

- Integration with existing systems

Quality Testing

Comprehensive testing protocols ensuring every component meets rigorous automotive industry standards and specifications.

Our comprehensive quality testing ensures that every component we produce meets or exceeds automotive industry standards. Our ISO-certified testing lab is equipped with advanced measurement and analysis tools to validate dimensional accuracy, material properties, and performance characteristics. Our testing capabilities include: - Dimensional inspection using coordinate measuring machines (CMM) - Material composition analysis - Environmental stress testing - Impact and durability testing - Functional performance evaluation We maintain detailed quality records for full traceability and can provide comprehensive test reports with each shipment.

Key Features

- ISO 9001 and IATF 16949 certified processes

- Advanced metrology equipment

- Environmental aging chambers

- Mechanical load testing

- Chemical resistance validation

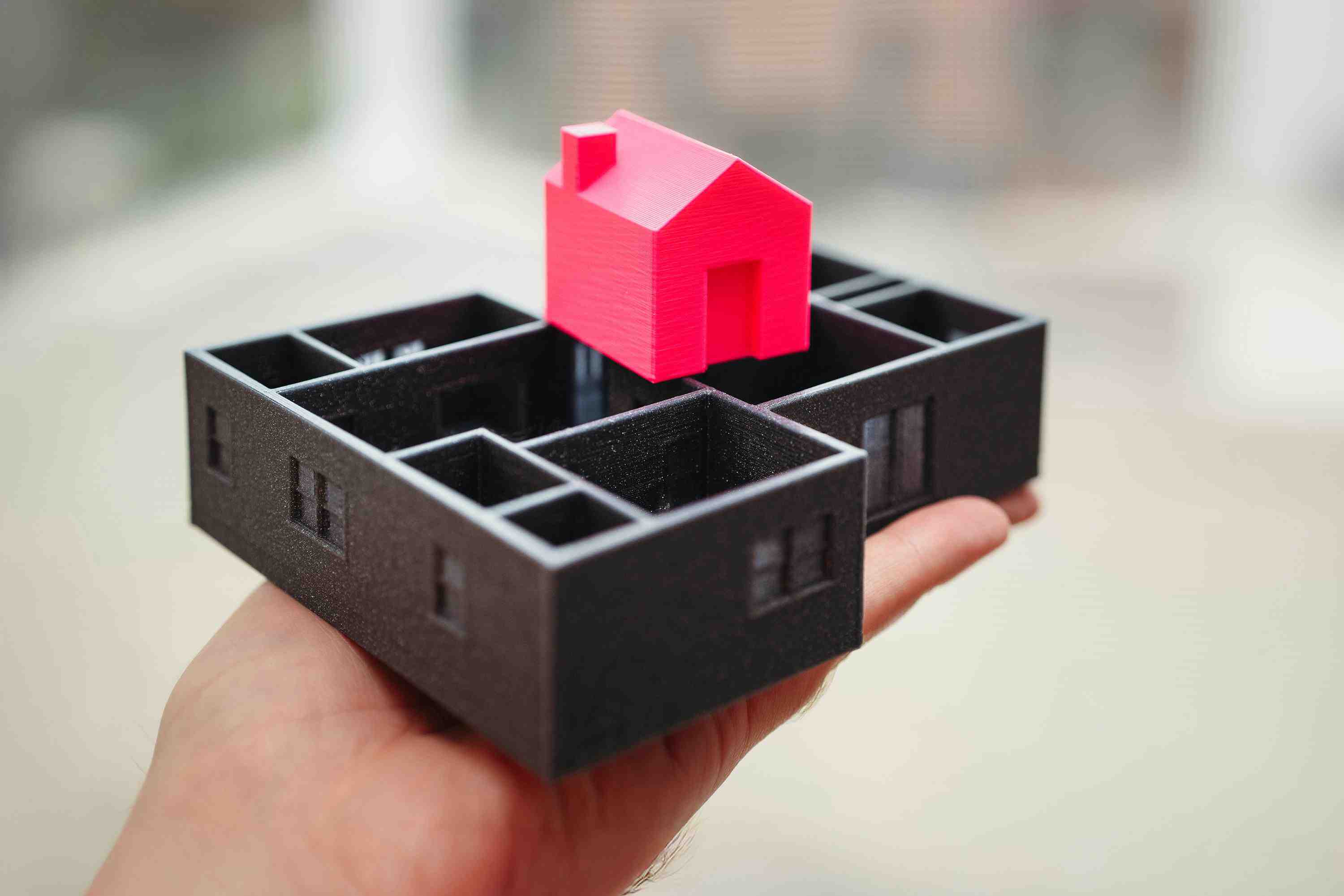

Rapid Prototyping

Quick turnaround prototyping services that accelerate development cycles and validate designs before full production.

Our rapid prototyping capabilities accelerate your product development cycle by quickly transforming concepts into physical prototypes for validation. We offer multiple prototyping technologies to meet different requirements for accuracy, material properties, and cost-effectiveness. Our prototyping services include: - 3D printing (FDM, SLA, SLS, MJF) - CNC machining for high-precision prototypes - Urethane casting for production-like parts - Prototype tooling and low-volume injection molding - Functional testing and validation With quick iteration cycles, we help you optimize designs and identify potential issues before committing to full production tooling.

Key Features

- 24-48 hour turnaround on simple prototypes

- Production-grade materials

- Functional testing capabilities

- Design refinement recommendations

- Smooth transition to production

Technical Support

Ongoing technical assistance and consulting to optimize component integration and performance in final applications.

Our commitment to your success extends beyond component delivery with comprehensive technical support services. Our experienced technical team offers guidance on component integration, troubleshooting, and optimization throughout the product lifecycle. Our technical support services include: - Integration assistance during assembly - Troubleshooting and problem resolution - Performance optimization recommendations - Field service and on-site support - Training for your technical team We view our relationship as a partnership and are dedicated to ensuring the optimal performance of our components in your applications.

Key Features

- Dedicated technical account managers

- Regular performance reviews

- Documentation and training materials

- On-site technical visits when needed

- 24/7 emergency support for critical issues

Ready to Discuss Your Project?

Our team of experts is ready to help you find the perfect plastic component solution for your automotive application.